One day several years ago, I happened to notice that the little light inside my doorbell button/switch was dark. From taking apart a doorbell button long ago in my youth, I knew that they had a regular incandescent lamp inside of them. Due to the era in which the house was built (2002), I assumed that this one was also illuminated with the same type of lamp, so I decided to take this one apart and see for myself. I figured that there was little risk with disassembling the button, since I was already planning on buying a replacement anyway. To echo those infamous words, “What could go wrong??”.

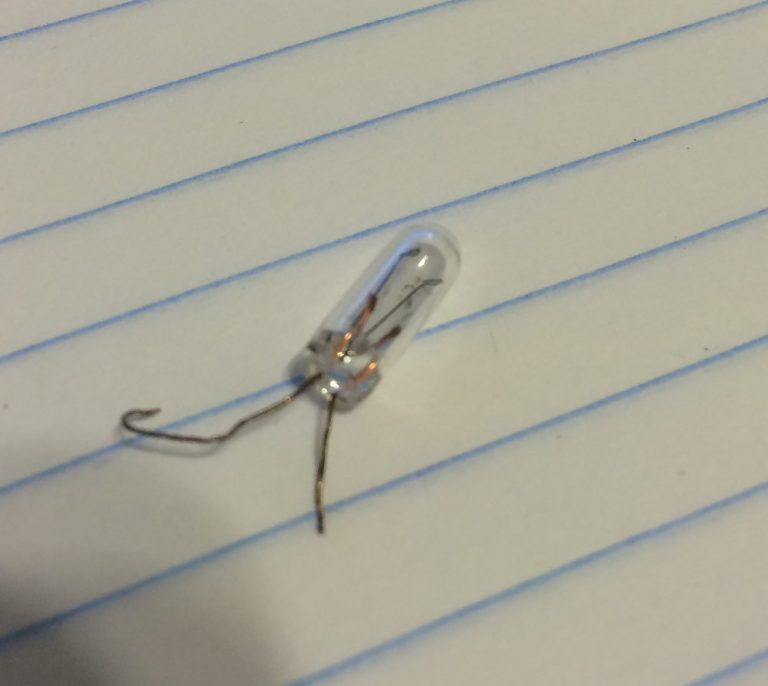

Upon taking the button apart, my suspicions about lamp type were correct – it was a classic incandescent bulb. I checked it with an ohmmeter and there was indeed an open in the bulb. The filaments of these lamps are very minuscule and incandescent bulbs by their very nature don’t last forever, even when driven at a lower voltage than what they are rated. In taking a closer look at the bulb, I could see that the filament had indeed gone BLOINK!

My next step was to find out what sort of voltage and type of current (AC or DC) the doorbell was being powered by. This would determine how I would approach replacing the incandescent lamp with an LED. Putting a multimeter on it, I was able to determine that it was indeed an AC power supply of approximately 16v AC (I recall seeing a transformer for it in the attic when I was messing around up there previously for a repair to the PCB for my furnace).

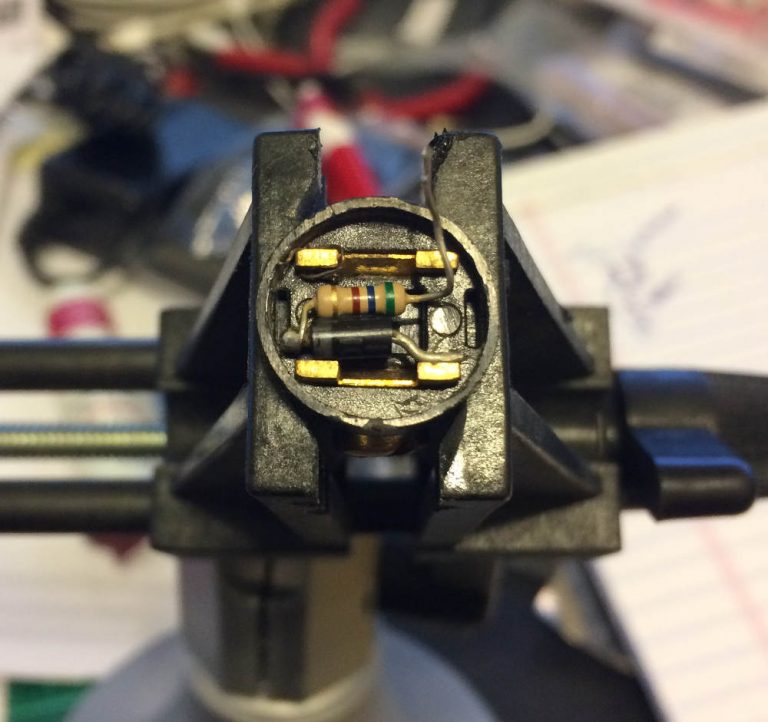

According to the specs for the cool-white color LED that I was planning on using, it had a forward voltage of 2.6v and and a current of 20mA. I elected to use a single 1N4001 power diode to lop off one side of the AC sine wave, knowing that there would be some additional voltage drop as well, due to the resistance of the diode. Attaching the diode to one leg of the power supply I measured the output voltage at approximately 8 volts. Using an online calculator for LED’s, it gave me a recommended value of 270Ω for resistor. The particular LED I was planning on using was pretty bright at that resistance value, so I messed around with a few different resistor values, finally settling on a 560Ω resistor.

There wasn’t a lot of room to work with inside this switch. I had wanted initially to try and incorporate a smoothing capacitor to reduce the pulsed DC flicker caused by the “rippled” DC coming from the diode (this happens when you only use a single diode to perform half-wave AC rectification), but the package just did not allow it. I put the base in my Panavise and went to work. After lots of bending of the component leads and test fitting, I was starting to come up with something that would fit the envelope.

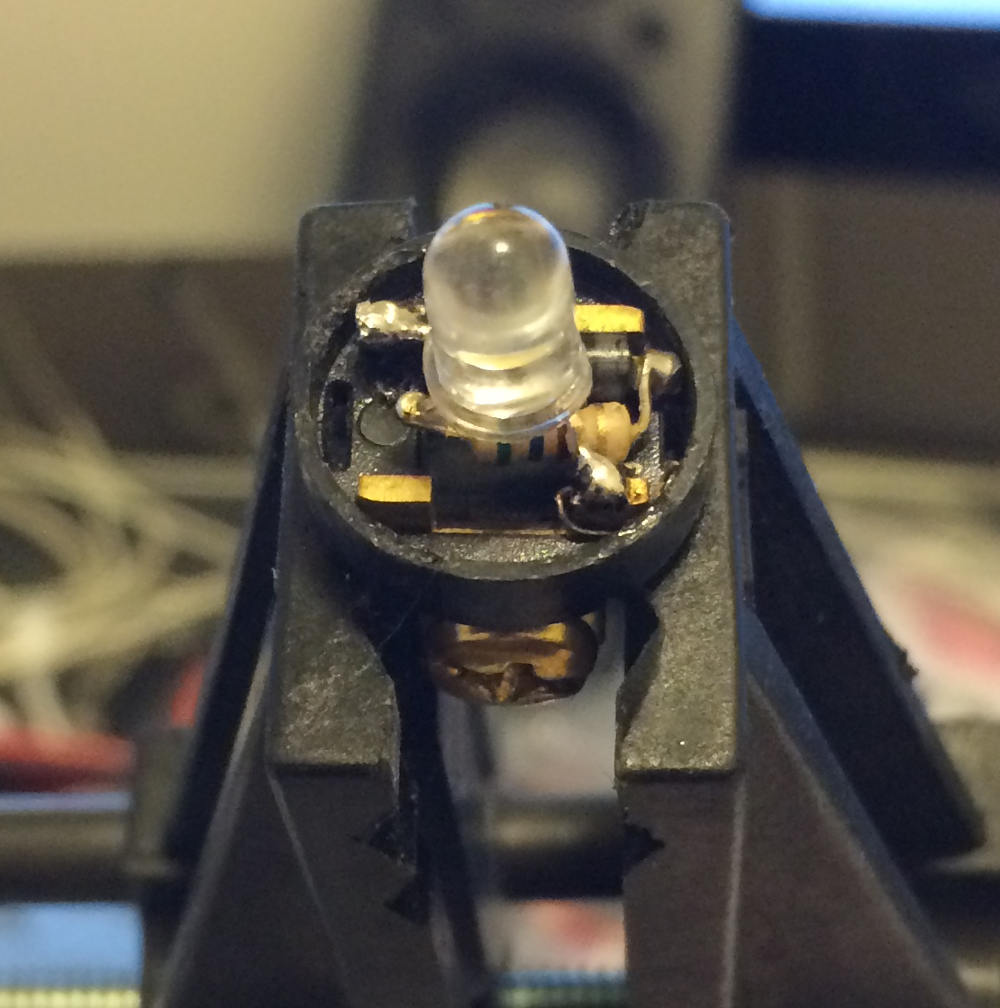

The final piece of the project was installing the LED. In looking at the completed electrical guts for the switch, it looked like I had come up with something that was going to work.

However, upon reinstalling the button, there was not enough room to allow sufficient travel of the button to close the contacts of the switch. No worries! Mr. Dremel to the rescue! I cut off the tip of the LED, which created enough room for the full travel of the button. This bit of downsizing inspiration came from my friend Rocky Allguire, a model railroading friend from back in my high school days. In what was almost an art form, he used files to reshape LED’s into small, stackable rectangular packages to build working replicas of “searchlight” type railway signals. They were probably the most realistic looking and operating signals I have ever seen. Of course, that was in the days long before the amazing component miniaturization and SMD components we have today were commonplace. With the tiny components today, a tiny circuit board with SMD LED’s resistors and diodes could easily fit in the space inside this doorbell switch!

I put the entire switch and faceplate back together, wired it up and voila! I had a working doorbell light again!

All in all, it was a simple fix using some electronics parts I had on hand and the whole thing really only took about an hour or so to do from start to finish. It’s not perfect, as a minor ripple can be seen out of the corner of my eye when walking past the doorbell button (this was due to no space for additional filtering components as mentioned earlier). But, it saved me a trip to the hardware store for a new switch, and I used that time instead to go out on a dinner date with my sweet (and patient) wife! 😀

Epilogue: This little improvised repair was done back in 2016 and the little lamp was still working when we moved to a new home in the summer of 2020. I have not been back by the old place to see if it is still working. With all of the tantalizing home security gadgets out there these days, I’m sure it has probably been replaced by some video doorbell, but this quick little repair served its purpose well.

Dennis J. Holmes

August, 2021